Elevate Your Experience

CORE Suspension by TracTive: Lightweight Sportscar Suspension only available from RaceShocks UK

Easily Customizable

Tailor your website to your liking with endless options to personalize the design and functionality.

Blazing Fast

Experience lightning-fast page load speeds for optimal user experience and SEO ranking.

SEO Optimized

Built with search engines in mind, achieve higher rankings and more traffic with optimized code.

Discover a new way to build website

Get online quickly with easy-to-use Full Site Editor builder

01

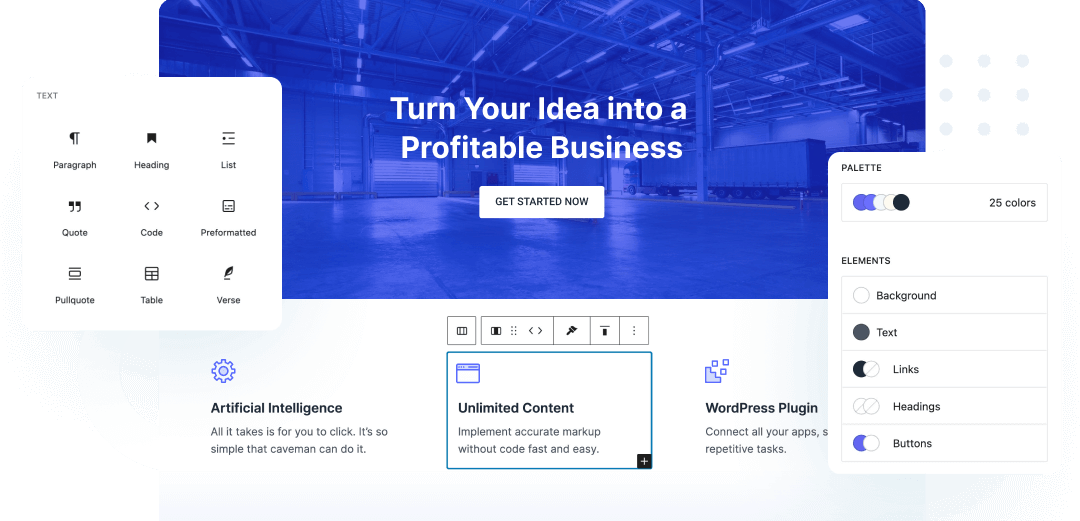

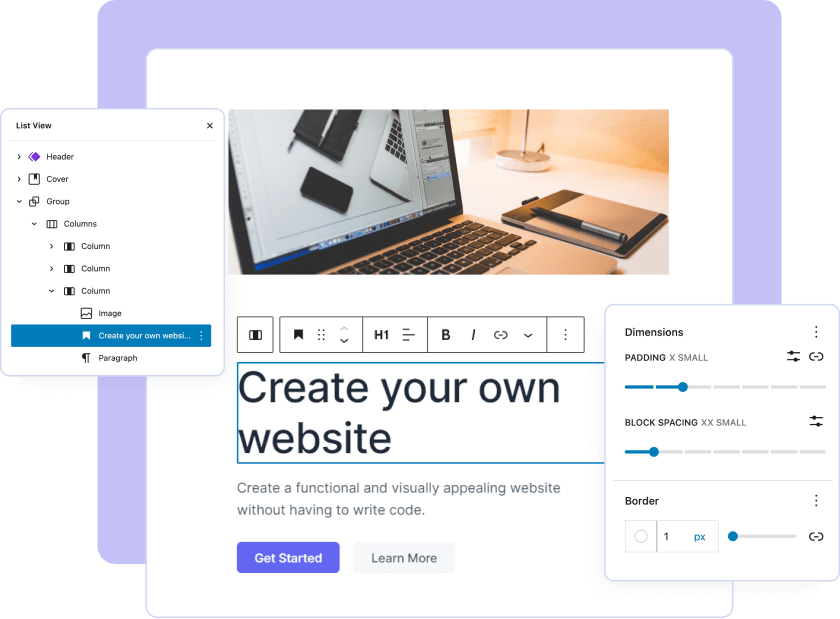

Visual editing experience

Customize the entire website layout, including the header, footer, and all other template parts. With FSE, we can create and edit templates for their entire website, including single posts, archive pages, and custom post types.

02

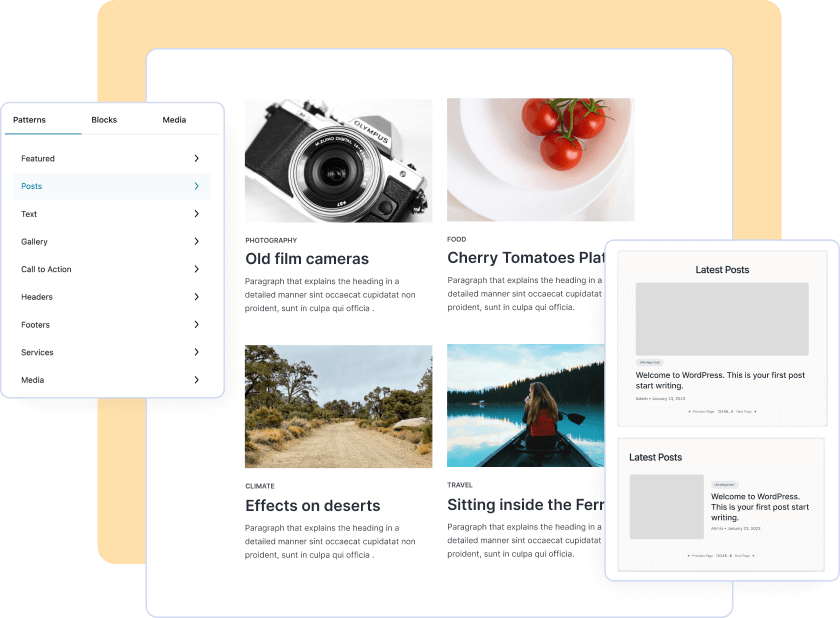

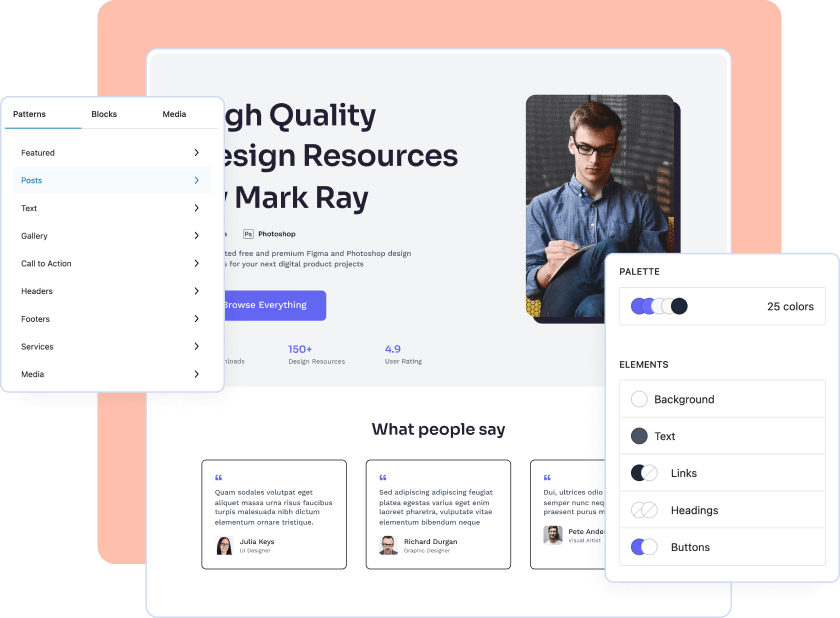

Innovative block patterns

Block patterns are pre-designed block layouts that we can easily insert into their content. These patterns can help to save time and create visually appealing designs. Allows us to create custom themes using the block-based template.

03

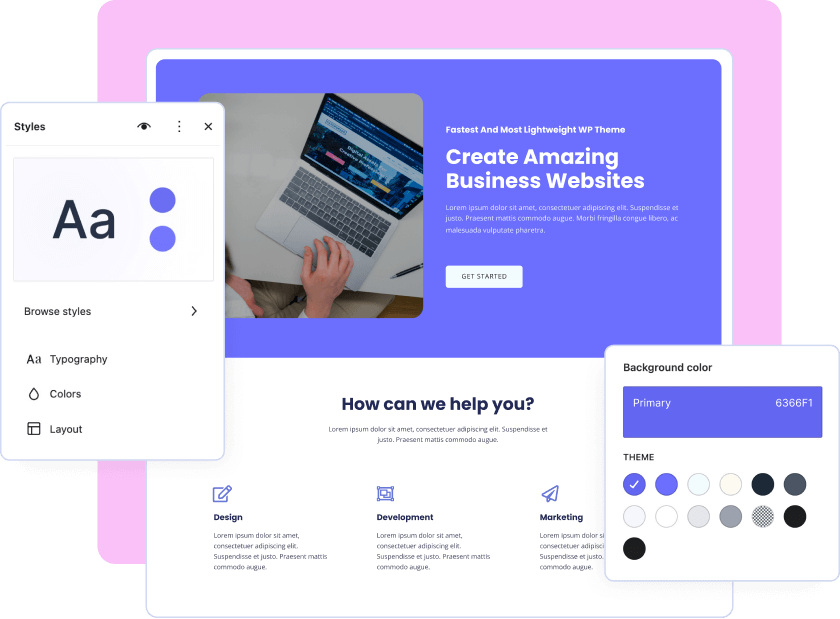

Beautiful global styles

Global styles enable us to create and apply consistent design elements across the entire website, including typography, colors, and spacing. Providing us with more control over our website’s look and feel.

Testimonials

See what people have to say about us

Darlene Robertson

Web designer

Highly recommended!

This theme made the process of building my website a breeze. The drag-and-drop interface was easy to use and the templates were customizable.

Jacob Jones

Freelancer

Endless customization

Endless customization options and responsive design, plus great customer support. Highly recommend!

Ralph Edwards

Marketing Coordinator

Great on any device

I’ve used a few different website builders over the years, and this one is by far the best. The responsive design ensures that my website looks great on any device.

Leslie Alexander

Business owner

Easy to use

As a small business owner, I needed a website that was affordable. I was able to create a beautiful website that represented my brand.

Brought to you by the creators of

Everything you need to create amazing websites

Interactive design tools and its many customization options to customize anything and everything needed to build the fully-functional website of your dreams.

Frequently Asked Questions

What is Full Site Editing?

Full Site Editing (FSE) is a feature in WordPress that allows users to visually design and customize their entire website, including the header, footer, and other template parts.

What are some benefits of using Full Site Editing?

Full Site Editing provides a more user-friendly, streamlined approach to website design and customization. It allows users to see changes in real-time, provides more control over design elements, and enables developers to create more custom blocks and templates.

Can I use Full Site Editing on my existing WordPress website?

Yes, you can use Full Site Editing on an existing WordPress website by installing a compatible theme that supports the feature.

Do I need to know how to code to use Full Site Editing?

No, Full Site Editing does not require knowledge of coding or web development. The drag-and-drop interface and pre-designed templates make it easy for users to create a professional-looking website without any coding experience.

Latest from the blog

Build your own website

Take your website to the next level!